Choosing a hot melt glue machine is no easy task. There are plenty of factors to consider, as the system has to match all your needs. There are also a lot of systems to choose from, including different brands, designs, and controls.

Altogether, if you do find the right system, you can improve your efficiency and your bottom line.

What to Consider When Choosing a Hot Melt Unit

Having been in the hot melt industry for over fifty years, we have worked with manufacturers using hot melt dispensing systems for packaging, product assembly, and more. While many manufacturers get so focused on a brand and go from there, there are other important factors to consider.

Our team breaks down how to choose a hot melt glue system that best meets your needs, including the top factors to consider.

Why?

The first thing you should think about is why you are looking for a new hot melt system. What are your pain points? Clearly identifying why you want a hot melt system can shed some clarity on your needs and priorities. Especially if you are having issues with your current system, you will want to avoid repeating these mistakes with your new hot melt glue machine.

Some people are looking to bump up their throughput. In this case, simplicity in design and ease-of-use may be your priorities. Others may have a specific problem with their current melters that they are trying to fix. A common pain point we see, for example, is adhesive charring. In this case, switching to a tankless hot melt system may be worth investigating.

Current System

The first question we often ask a manufacturer is if they currently have any hot melt units and what they are. It is also not uncommon for manufacturers to have more than one type of hot melt unit from different brands.

Do you like your current unit? If you have two different machines, do you favor one over the other? Why? Are your machines still being manufactured? Do you want to eventually have all the same systems?

The answers to these questions can help you get a good starting point for your decision. If you like your current system, it could be an indicator that you should get a similar model. On the other hand, it may alert you that you need to switch systems. For example, Nordson has phased out some of its ProBlue series, so it is likely wise to invest in another system where customer support and replacement parts are more readily available.

Throughput

Throughput is another important factor to consider when choosing a hot melt glue system. Too small a system, and you could hurt your efficiency and throughput; too big a system, and you could experience less energy efficiency and excess charring.

You want a system that can comfortably meet your melt-rate needs. You should consider the following:

- Whether your production is continuous or experiences frequent stops

- The number of applicators you need running at the same time

- Your line speed

- Your current demand, as well as future demand

If you are just beginning, have a smaller throughput, and have no immediate plans for expansion, you can likely get by just fine with a smaller unit. If you have a higher throughput to begin with or are looking to increase your throughput, choosing a hot melt system with a higher melt rate may be a better option.

Adhesive

The type of adhesive you are using and its shape will also determine which hot melt dispensing system you choose. Not all bulk hot melt systems can be used with every bulk hot melt. While you can switch adhesives, it is usually better to find a system that matches what you are already using. PUR adhesives, for example, typically require equipment designed for two-component or high-temperature operation rather than general-purpose hot melt machines.

Similarly, some systems are also only compatible with certain adhesive shapes. While one system can handle pellets, slugs, and pillows, another system may only be compatible with pellets. You should also review the recommended operating temperature range of your adhesive.

Production

Along with being compatible with your adhesive, the bulk hot melt glue machine you choose needs to be compatible with your production process and facility. You should consider the following:

- Available space

- Maximum hose/applicator power capacity

- Voltage

- Startup time

If the hot melt tank you choose is not compatible with your warehouse setup, it is useless. Also, you want to choose a hot melt glue system that is going to increase the efficiency of your production process, not potentially hinder it.

Cost

Another important consideration during the hot melt glue machine selection process is cost. Bulk hot melt machines should be viewed as long-term investments. You want to not only consider your initial setup costs but also the lifetime and total cost of ownership of the hot melt glue tank you choose.

A tankless system, for instance, may cost more initially but could reduce maintenance and replacement parts costs related to charring as well as offer a faster startup time. For some manufacturers, this could lead to long-term savings.

Need More Help?

Selecting a hot melt machine is about meeting your specific needs. While you may now have a better understanding of how to choose a hot melt glue system, we understand that you may still have questions or need help identifying the best system for you.

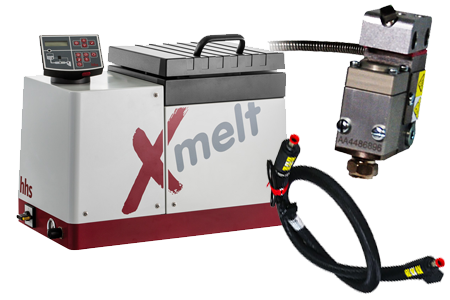

You can browse our selection of bulk hot melt glue machines or reach out to us for more help. Contact us, and you can speak with one of our hot melt experts. They can not only answer your questions but also provide you with glue machine recommendations tailored to your unique needs.

Hotmelt.com is not affiliated with the Nordson® Corporation. All OEM part numbers are for reference only. Nordson® is a registered trademark of the Nordson® Corporation.