The last thing any manufacturer wants is to halt production because of an issue with their machines. Unfortunately, this is an all-too-common occurrence and adhesive charring is often to blame.

What is Adhesive Charring?

Adhesive charring refers to burnt or “charred” glue that has broken down and formed a gel after prolonged exposure to heat. Over time, this burnt black glue can build up and cause major problems like clogged hoses, uneven adhesive application, or even downtime in production.

Some potential causes of adhesive charring include:

- Running a hot melt system that is heated but idle

- Exposing the adhesive to air

- Getting contaminants in the adhesive

- Exposing the adhesive to temperatures that are too high

- Not properly cleaning or maintaining machines

- Using low-quality hot melts that degrade over time

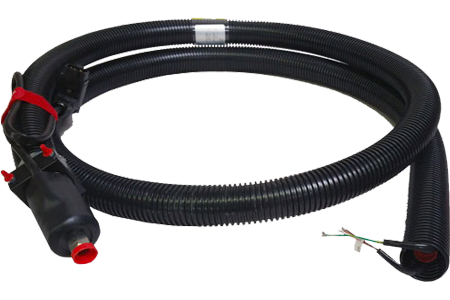

- Bending or flexing hot melt hoses repeatedly

While there are many potential issues that can arise, a lot are avoidable.

How to Prevent Hot Melt Adhesive Char

Adhesive charring from hot melt can cost you both time and money. It is a pain to troubleshoot and clean. It can also kill your company’s productivity from unnecessary downtime. Instead of dealing with the issue after the fact, try stopping it in the first place. These tips on how to prevent adhesive charring may help.

1. Set the Right Temperature

It is important to run your hot melt at the right temperature. Higher temperatures, especially during idle times, are the biggest culprits of hot melt charring. As an added precaution, a temperature setback can decrease the chances of the adhesive degrading by gradually decreasing the temperature in the unit when it is not actively in use.

2. Perform Regular Maintenance and Cleaning

One of the best ways to avoid adhesive char buildup is to do regular maintenance and cleaning of your equipment. Make sure you flush your tank regularly when you change adhesives. A product like EnviroFlush can help make this process easier.

Along with cleaning the tank, be sure to also keep the hoses clean. Wipe off dust and debris daily. Also, wipe away any hot melt on the hose fittings or the hose braid while wearing safety gloves. This will reduce the likelihood of hot spots in the hose and kinking. While trying to clean out the insides of your hoses sounds like a good idea, it can cause more harm than good. Using a snake will scratch the walls of your hose and cause them to collect adhesive char even faster.

3. Fill the Tank to the Right Level

You want your melt tanks to be filled to the right level with adhesive. A tank that is low on adhesive will leave residue on the walls that is exposed to oxygen. This combination of heat and oxygen can make glue burn quicky. Avoid this issue by keeping the tank full.

Rather than having to monitor and refill the tank, you could also go tank free. This Graco InvisiPac hot melt glue melter uses melt on-demand technology to avoid buildup in the tank and significantly reduce hot melt charring.

4. Use the Right Equipment & Adhesive

For optimum efficiency (and to decrease char in hot melt adhesives), you want to ensure that you use the right machine, tank, hose, and adhesive. While you may save money on bargain equipment, it could cost you in the long run. Low-quality adhesives can degrade and form char more quickly. The wrong size tank could cause your adhesive to sit for too long and burn. Low-quality hoses and machines have shorter work lives and may not be as effective at preventing the buildup of hot melt charred glue. You may also want to consider an inline filter between your gun and hose to trap burnt glue before it clogs your guns or nozzles.

5. Replace Damaged or Old Equipment Immediately

Damaged equipment can quickly lead to disaster. If your hot melt hose is leaking or clogs a new nozzle, it is time to change it out for a new hose. Old equipment can also become less efficient and lead to adhesive charring faster. Waiting to replace equipment may only cause more damage with longer downtimes and higher costs to find a solution.

Replacing equipment can be costly, but we may be able to help. With our buy back program, you can get cash or credit when you trade in your old Norson® machine. We also have a refurbishment program to help you revitalize old Nordson® machines.

You may even be able to get new equipment for free with your regular adhesives purchase. Find Out More.

Let Us Help You Find a Solution

Not sure what the best solution is for your needs? Our adhesive experts are here to help. When you contact us, you can chat with someone about any issues you have as well as your regular adhesive needs. Our experts will then guide you to a custom adhesive solution to help you reduce adhesive char (or any other problems you may be facing).

Hotmelt.com is not affiliated with the Nordson® Corporation. Nordson® is a registered trademark of the Nordson® Corporation.