Bulk Hot Melt Tanks

A Bulk Hot Melt Tank For Every Application

At Hotmelt.com, we offer a wide range of industrial bulk hot melt tanks that cater to a variety of applications, from packaging to product assembly — and everything in between. Our selection includes specialty melters and direct replacements for popular brands like Nordson, ITW, and more. With our extensive inventory, you can be sure that you'll find the right bulk hot melt tank for your specific needs.

Unsure which tank is right for your application? Don't worry. Our team of hot melt experts is always available to answer your questions and guide you through your decision. Contact us for help finding the perfect hot melt dispensing solution for your application needs today.

Featured Brands

Related Categories

FAQs About Bulk Hot Melt Tanks

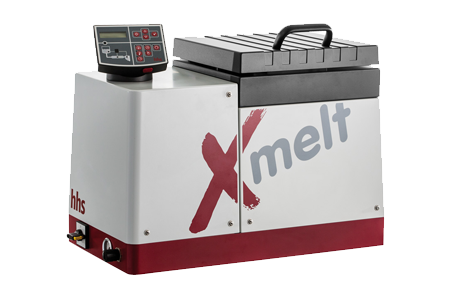

A bulk hot melt tank is a large container used for melting and storing large quantities of hot melt adhesive. These tanks are ideal for industrial settings where large amounts of adhesives are needed for production or packaging.

A bulk hot melt tank works by heating solid hot melt adhesive pellets or blocks to a molten state, which can then be dispensed through a hose or nozzle for application. Tanks typically have a heating element and temperature control system to maintain the adhesive inside at a desired temperature. Some tanks also have agitators or mixers to ensure consistent heating and melting of the adhesive pellets.

Using a bulk hot melt tank offers several advantages, including higher production rates, reduced downtime needed for refilling, and increased efficiency in adhesive application. These tanks improve adhesive quality by ensuring consistent melting and temperature control. Bulk hot melt tanks can also be customized to meet specific production needs, like different adhesive types or flow rates.