Table of Contents

In packaging applications, adhesive selection plays a critical role. The right adhesive can improve efficiency, reliability, and overall productivity. The TECHNOMELT SUPRA hot melt line from Henkel is one such collection of adhesives for different packaging applications.

We break down a bit more about these products, including their key properties and applications.

What is the TECHNOMELT SUPRA Series?

The TECHNOMELT SUPRA products are a series of high-performance hot melt adhesives from Henkel that are formulated primarily for packaging applications. Compared to the standard TECHNOMELT line, the SUPRA products are often considered higher-performance hot melts.

Beyond traditional case and carton sealing or tray forming, some SUPRA hot melts are made for more niche applications in the packaging industry, including deep-freeze packaging or food packaging. Some products also have other beneficial properties, such as great thermal stability, high mileage, low odor formulation, low application temperature, or the ability to bond difficult substrates.

SUPRA Product Spotlights

The TECHNOMELT SUPRA adhesive line includes a diverse collection of hot melt adhesives engineered to meet the demands of a wide range of packaging applications. To help you find the right adhesive for your application, our team is highlighting a few of our favorites and what makes them unique.

One of the most popular SUPRA hot melt adhesives, the TECHNOMELT SUPRA 100 is a high-performance, general-purpose hot melt for end‑of‑line packaging applications. It offers both great cold resistance (freezer-grade properties) as well as heat resistance for packaging exposed to extreme temperatures. The adhesive also has excellent processing properties and can provide clean application even at higher production speeds.

This metallocene is compliant with FDA 21 CFR 175.105 regulations for use in applications with indirect food contact. It is also suitable for high heat as well as deep freeze applications. Fast-setting with a high initial tack, this product is compatible with high-speed production lines.

A cool application hot melt, this adhesive is specially formulated with a lower application temperature that can decrease safety concerns, reduce energy costs, and increase equipment service life. It is also FDA-compliant for indirect food contact and has a high thermal stability.

This high-performance hot melt offers the highest adhesion of the SUPRA hot melt product line and is compatible with difficult-to-bond substrates. It has a high hot tack and a high heat resistance. The adhesive is also suitable for deep-freeze packaging and boasts high mileage for more coverage with less adhesive.

To make it a little bit easier to compare, our team has added a chart below of the highlighted SUPRA adhesives.

|

Product |

Base Chemistry |

Application |

Working Temperature |

Key Properties |

|

SUPRA 100 |

Polyolefin |

End-of-line packaging |

320°F to 374°F

|

High bond strength, thermal stability, fast setting, clean processing, heat and cold resistance |

|

SUPRA 126 |

Polyolefin |

Case and carton sealing |

325°F to 375°F |

Thermal stability, fast-setting, high initial tack, heat and cold resistance |

|

SUPRA PRO 450 COOL |

Metallocene |

Food-safe packaging |

250°F to 300°F |

High thermal stability, low operating temperature |

|

SUPRA 350 HT |

Polyolefin |

Difficult-to-bond substrates, deep freeze packaging |

320°F to 374°F |

High adhesion, high heat resistance, high hot tack, high mileage |

These products are just a few adhesives in the product line. Shop our collection of Henkel TECHNOMELT SUPRA hot melts.

Factors to Consider When Choosing a Product

Even if you have a specific TECHNOMELT SUPRA hot melt adhesive in mind, it is important to determine if it is the right fit before rolling it out to your production line. Some factors to consider include:

-

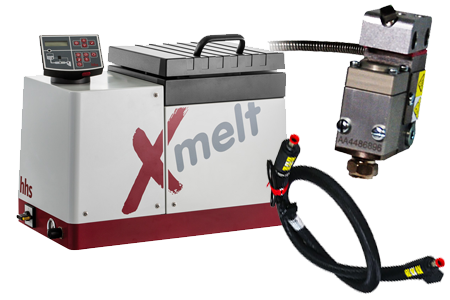

Equipment & Process Compatibility- Ensure your current hot melter is compatible with the chemistry, viscosity, and temperature range of your hot melt, or you may need to invest in new equipment. In some cases, the equipment is compatible, but you need to recalibrate it before use with the new adhesive to get optimal results.

-

Substrate Materials- Some SUPRA glues are compatible with more difficult-to-bond substrates, while others are not. Make sure you choose one that is compatible with your materials.

-

Environmental Temperatures- Many SUPRA packaging adhesives can withstand extreme temperatures, but check that the product you are interested in is compatible with the temperatures in your production, storage, and shipping.

-

Set Time- Some SUPRA hot melt adhesives have faster set times than others that will better suit high-speed production.

-

Regulatory Compliance- For operations that package food, having adhesives that meet FDA requirements on food contact is critical.

Even if a product meets all your specifications, it is important to run trial lines to check how the adhesive fits into your production process as well as how it performs in the given environmental conditions.

Need Something Else?

The Henkel TECHNOMELT SUPRA product line consists of high-performance adhesives for packaging applications with different requirements. They are a high-quality and trusted solution for many businesses, but if you do not see the product specifications you need, we still want to help.

We offer an extensive collection of adhesives for packaging from Henkel and other top brands. One of our adhesive experts can also provide you with a customized product recommendation if needed.