Table of Contents

Your hot melt system can have a direct impact on your efficiency and costs, so you want to make sure you have the best melter for the job. While there are options to choose from, the Graco InvisiPac HM 25c stands out for its tankless design compared to traditional hot melt systems. But how does it work? And is it worth it?

Having worked with hot melt equipment for over 50 years, we review the InvisiPac HM 25c tankless hot melt system and share our honest thoughts on its design, efficiency, and cost. Then you can decide for yourself whether or not it is the best fit for your job.

What Is the Graco InvisiPac HM25c Tankless Hot Melt System?

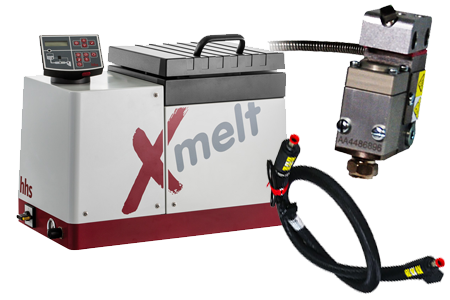

The InvisiPac HM25c from Graco is a tank-free hot melt system that uses melt-on-demand technology for a first-in, first-out (FIFO) melt process. Instead of having hot melt sit in a heated reservoir until use, like with traditional melters, the HM25c melts the bulk adhesive as needed and immediately delivers it to the applicator for dispensing.

The HM25c includes performance reporting and supports four to eight dispense channels. With a melt rate of around 25 pounds per hour and a fast startup of about 10 minutes, the InvisiPac HM 25c is well-suited for mid- to high-volume applications. The system is primarily used for end-of-line packaging.

Advantages of the Graco InvisiPac HM25c

The biggest benefit of the InvisiPac HM25c is its tank-free design. Traditional hot melt systems rely on a heated tank to hold the adhesive during production. This issue with this setup is that the adhesive can be exposed to oxygen, contaminants, and prolonged heat. This exposure can result in oxidation and adhesive charring that can clog nozzles, hoses, and filters. Ultimately, charring can decrease adhesive quality, increase maintenance costs, and cause unnecessary downtime.

The InvisiPac HM25c tankless hot melt glue system eliminates the tank and significantly reduces the problems that come with it. Instead, the bulk hot melt is fed directly into a compact melting chamber where it is heated and dispensed on a first-in, first-out basis. This design helps reduce adhesive degradation and char buildup for cleaner operation. For manufacturers that struggle with clogged nozzles, frequent maintenance, wasted adhesive, or inconsistent adhesive performance, switching to the HM25c tankless glue melter can have a meaningful impact on their business.

Another benefit of the HM25c system is its fast startup time of around ten minutes. Because of its tank-free design, the system is able to reach operating temperature faster than most tank-based melters. This reduced time can shorten startups during shift changes or restarts and improve overall efficiency.

These advantages are most noticeable in facilities with frequent startups, shutdowns, or changeovers, as well as operations using adhesives sensitive to prolonged heat exposure.

Some other pros of the InvisiPac HM25c tankless hot melt system include:

- Limited operator intervention needed

- Advanced pattern control options

- Robust reporting for visibility

- Generally lower cost of ownership because of reduced maintenance and spare parts costs

Limitations of the HM25c

While the InvisiPac HM25c offers clear benefits, it is not the right solution for every operation. Understanding its limitations can help you avoid unmet expectations.

The biggest potential hiccup with the Invisipac HM25c is adhesive compatibility. The system is designed to be compatible with different chemistry pellets and PUR slugs. If you are currently using pillows, slats, or another form of bulk hot melt, this could be problematic. In some cases, you may be able to find the same adhesive or a comparable one in a compatible form. Our team can provide you with a recommendation if needed.

Another potential con to the Graco InvisiPac HM25c is the limited number of channels. The InvisiPac HM25c is able to accommodate up to four or eight channels. If your application requires more, a different system may be more suitable.

How the InvisiPac HM25c Compares to Traditional Tank Melters

To give you more information, we not only reviewed the InvisiPac HM25c but also how it compares to some other popular systems used for similar applications.

| Specification | Graco InvisiPac HM25c | Meler Micron+ 20 | ProBlue 10 | ProBlue Liberty 14 |

|---|---|---|---|---|

| Melt rate | ~25 lb/hr | ~ 42 lb/hr | ~24 lb/hr | ~30 lb/hr |

| Adhesive form | Pellets and PUR slugs | Various, depends on adhesive chemistry | Various, depends on adhesive chemistry | Various, depends on adhesive chemistry |

| Tank Capacity | Tankless | 19.7 L | ~10 L | ~5-10 L |

| Number of hose ports | Up to 6 | Up to 6 | 1-2 | Up to 9 |

| Startup time | ~10 minutes | ~30 minutes | ~20-30 minutes | ~30-60 minutes |

| Max fluid temperature | ~400°F | ~400°F | ~450°F | ~400°F |

Product specifications, features, and performance information are based on available data at the time. Specifications may change without notice. Always consult an expert to confirm current specifications and suitability for your application.

Is the Graco InvisiPac HM25c Right for Your Operation?

After a full product review of the Graco InvisiPac HM25c, we believe that this system is a great choice for medium- and high-volume packaging applications. The tankless and melt-on-demand design makes it ideal for manufacturers who are looking to decrease their maintenance costs and wasted adhesive. The setup time is also faster than most systems to decrease downtime between runs. This can be a great driver of efficiency for businesses.

If you have experienced consistent problems with charring or have a production process that includes regular line stops or changeovers, the Graco InvisiPac HM25c tankless system can be a great investment for your business. Just be sure to check compatibility with your adhesive and production process.

Looking for Something Else?

Overall, our review of the InvisiPac HM25c from Graco is a great option for many businesses as its innovative design can minimize common issues with other traditional melters. That being said, we understand that everyone’s needs are unique. If you are looking for a different volume or another design, we still want to help.

We carry a diverse collection of hot glue melters from different brands and for different needs. If you have questions or are looking for a recommendation, you can also reach out to our team.

Hotmelt.com is not affiliated with the Nordson® Corporation. All OEM part numbers are for reference only. Nordson® is a registered trademark of the Nordson® Corporation.