Partially due to an increase for packaging needs in Asian-Pacific and South American markets, the adhesive industry is positively booming. According to Business Insider's report, that trend is on track to continue. Most researchers expect the market to increase by 60 percent from $7.39 billion in 2016 to over $12 billion by 2023.

What often happens in cases of such extreme growth (After all, the predicted compounded annual growth rate is 7.3 percent!) is that production of all the important components has to change to keep up with demand. And such is the case when it comes to the adhesives that are so vital to the hot melt industry.

This inevitably has led to a move away from organic compounds to synthetics that take the load off Mother Nature. Fortunately, the man-made compounds that are taking their place are similarly beneficial for the environment. We’re happy to report that the rising concern for the environment has had an overall positive impact on the hot melt adhesives industry by influencing the development of environmentally compatible adhesives and solvents, as well as greener manufacturing processes.

The Problem With Solvent-Based Adhesives and Cleaners

Solvent-based adhesives are widely used in the automotive, furniture, and construction industries. The liquid used to dissolve the polymer and form the adhesive bond is a solvent. Some solvents are flammable, many are poisonous, most evaporate quickly, and cleanup and handling typically requires special precautions. And unfortunately, solvents can harm the environment in several ways:

Soil Pollution

Solvents that manage to leach into the soil eventually contaminate groundwater. Not only can this kill plants and animals, the solvent contamination may go on to pollute drinking water.

Water Pollution

The runoff from solvent-based adhesives does not dissolve readily in water. That means that once they reach water, they can hang around for a while, poisoning anyone or anything that comes in contact with that water.

Air Pollution

Breathing in the fumes from quickly evaporating solvent-based adhesives poses serious health risks like asthma and lung disease. Solvents that enter the body often can be stored in the brain’s fatty tissue and adversely affect cognition later on.

Developing More Environmentally Friendly Adhesives

Hot melt adhesives are thermoplastic materials comprised of stabilizers, additives, pigments and polymers sold in solid, cylindrically shaped sticks or pellets. It’s melted and applied using a hot melt gun, sprayer or other extrusion device.

Because it doesn’t contain solvents, hot melt produces less pollution and has fewer environmental effects. Unlike adhesives based on solvents, you don’t need any special ventilation, nor will you have to worry about flammability.

And because it’s affordable, industries like construction high-volume packaging operations have taken to using this adhesive. That’s why governments, regulatory agencies and even environmental organizations support the use of hot melt over solvent-based adhesives.

Ethylene Vinyl Acetate (EVA) is the most frequently used hot melt because of its versatility. It’s easy for manufacturers to manipulate the plasticizer (wax or oil) to control the viscosity and tack so it can be used in a variety of dispensers, industries and applications. EVA is expected to continue to occupy the maximum share of the hot melt adhesive market. It’s also fortunately a more environmentally friendly adhesive that is not solvent-based.

These more environment-friendly, synthetic adhesives have low (or no) amounts of solvent in them in order to reduce the negative impact that solvents and their emissions can have on the environment. These more “Green” glues, such as the following, have superior mechanical strength and are process-friendly in many areas of the industrial market:

-

Two-part, room-temperature epoxies

-

Clear, single-part, silicone-based systems

-

UV-curable, low-viscosity adhesives

-

Low-VOC, solvent-free hot melt glues

- Water-based glues with novel ingredients such as polyurethane foam, latex foam, fibers from polyester, plastic, wood, rubber, jute and metal

Embracing Environmentally Friendly Cleaners

Just like solvent-based adhesives, cleaning solvents themselves take a pretty tough toll on the health of the environment and the people who come in contact with it. However, re-purposed and brand new cleaning solvents are working to balance process times and costs versus poor environmental effects.

Previous industry-standard solvents with high VOC solvents like 1,1,1-trichoroethane, Methyl ethyl ketone and Freon 113 are being replaced. Their less-harmful counterparts include detergents, soaps and other and more affordable, less expensive and easier-to-handle solvents with low VOC.

Aqueous Cleaners

There are three types of aqueous cleaners, which are ranked on their acidity level:

-

Acidic: used to remove oxide on metals; includes phosphoric, hydrochloric, citric and hydrofluoric acids

-

Neutral: work well for cleaning aluminum, but are too harsh for brass and copper

- Alkaline: these caustic solvents include sodium hydroxide and potassium hydroxide; used on steel to remove scale, rust and heavy oil

Non-Chlorinated Solvents

Non-chlorinated solvents including the following are meant to take advantage of the benefits of chlorinated solvents with fewer environmental hazards:

-

Acetone, mineral spirits and terpenes: common non-chlorinated solvents that perform well but are flammable and suffer from variable drying times

-

Methyl siloxanes and oxygenated solvents: these remove silicone oils but are flammable

-

Halogen-based solvents: fluorine is a common cleaner in this class; it has reduced flammability, low toxicity, and minimal harmful environmental effects

- Super-Critical Fluids (SCFs): SFCs like high-temperature, highly-compressed CO2 are great vapor degreasers, but they require an investment in specialized equipment

Henkel TECHNOMELT Green Cleaners

Henkel shows its devotion to sustainability and social responsibility in the adhesive and sealant industry by creating industrial cleaning products that are biodegradable and free of Class I ozone-depleting chemicals. In addition, Henkel’s TECHNOMELT cleaners extend the lifespan of hot melt equipment. By doing so, they reduce waste and pollution.

Choosing the Best Henkel TECHNOMELT Green Cleaner

Henkel makes a variety of cleaning agents to keep your hot melt machinery clean. Choose the best TECHNOMELT product from its line of solvents created specifically for your PUR projects.

Henkel’s TECHNOMELT PUR Cleaners 2 and 4 come in different viscosities to remove uncured PUR from hot melt equipment. Both varieties are suitable for all tank melters and are “reactive” to inhibit x-linking of TECHNOMELT PUR residue.

Henkel’s TECHNOMELT PUR Cleaner 7 is a more powerful cleaning agent that works on cured PUR hot melt. This cleansing oil is intended to clean, condition and extend the lifespan of rubber rollers.

Henkel’s TECHNOMELT PUR ME Cleaner is an oil-based solvent suitable for cleaning melt tanks, hoses, pumps and nozzle applicators. Because it removes charred, cured and uncured hot melt residue, it’s a great product for equipment repairs and refreshes.

Henkel’s TECHNOMELT PUR Cleaner All-in-One gel is guaranteed to remove cured PUR hot melt adhesive on platens and in hoses and nozzles. Its dwell time is 30 minutes at 100°C in platens and tanks and 160°C in hoses and nozzles.

Henkel’s TECHNOMELT PUR Cleaner 3030 & M-O-C is a powerful cleaning agent for hot melts and waterborne adhesives

Henkel’s TECHNOMELT PUR Cleaner 785A is a wax and release agent. The white flake plasticizer cleaner can be used as an effective replacement for other forms of hot melt equipment cleaners.

Lower-Cost Cleaning Products

Enviroflush Hot Melt Equipment Flushing and Cleaning Material

Infinity Melt's Enviroflush is a non-toxic and biodegradable cleaning solution for your bulk hot melt tank. With your tank set between 300 and 350 degrees Fahrenheit, simply let the solution circulate through your machine, scrap, and discard any remaining char.

Infinity Bond EnviroClean Hot Melt Equipment Cleaner

EnviroClean by Infinity Bond is ready to use with no mixing, it's non-toxic and biodegradable and will clean your equipment with optimal efficiency at a lower price point.

Improving Efficiency for the Environment

Reducing the use of harmful chemicals in adhesives and cleaners is only one step in keeping up with today’s environmental concerns for the hot melt industry. Reducing waste and energy use is another core tenet of operating an environmentally friendly organization.

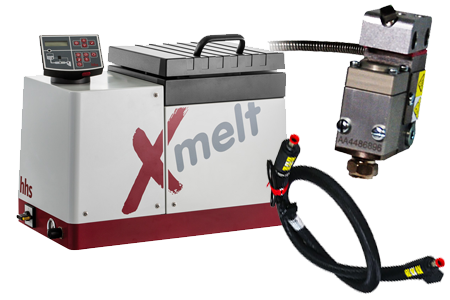

Leaders in the hot melt industry are embracing tankless bulk hot melt dispensing systems to improve the efficiency of their operations and shrink their footprint while keeping quality and safety intact. Tankless hot melt equipment uses a vacuum feed to draw adhesive pellets into a heating chamber. From there, the pellets are melted on demand and dispensed quickly.

They only draw a small amount of hot melt at a time, so heating is efficient and charred adhesive eliminated. It may also increase the longevity of bulk hot melt equipment, as it creates fewer instances for char to clog nozzles and cause fluid seal failures. You waste less product and your workers spend less time in maintenance mode. In some cases, material and production expenses have reportedly decreased as much as 50 to 75 percent.

Sure, the hot melt industry is booming — but that doesn’t mean Mother Nature has to suffer. We shouldn’t have to choose between the scientific advancements that make life better and preserving our environment. Cleaning up the hot melt industry starts with cleaning up the adhesives that are so valuable to its success. Man-made, solvent-free adhesives and cleaners are taking a huge bite out of the chemical footprint the hot melt industry will leave for posterity.

In addition, a simple step like improving the efficiency of our hot melt machinery and systems can reduce adhesive waste, cut down on energy use and increase the longevity of costly machinery.

At Hotmelt.com, we cherish the environment and are thankful that renewed concern for our planet has improved the hot melt adhesive industry and life for its workers in so many ways. If you’re interested in taking advantage of making your organization more green, just contact us online.