Tips for Power Adhesives Applicators

Whether you are seeking a quality glue gun that will hold up to the demands of an industrial environment or you already own and use one, the Power Adhesives line of glue guns offers a great range of features that can save time and money in many applications.

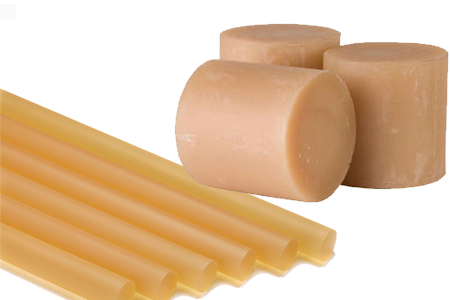

Tec models include:

- Simple but tough models that hold up to heavy use like the Tec 3500

- Glue guns with multi-load cartridges that let you go longer before refilling

- Air-assisted guns that reduce strain on operators like the Tec 6100

- Models that allow spray application

Several models also combine these features like the Tec 6300 that is an air-assisted spray gun or the Tec 7100 that is both air-assisted and handles multi-loaders.

No matter which model of industrial Tec glue gun that you own or consider purchasing for industrial use, there are five things you can do to keep your Tec glue guns running at optimum efficiency and extend their lifespans.

1. Allow time to warm up.

Glue guns must warm up in order to reach temperatures suitable for melting the glue used. Most glue guns take at least 10 minutes to reach their proper operating temperature, and the Tec models are no exception. Some models may be ready more quickly but giving it the full 10 minutes ensures your gun will be ready for operation. This is especially important with spray models.

If you don't allow the gun to warm up completely, it may not properly melt the glue and your products may fail due to the lack of adhesion. Also, before a gun is properly warmed up, any attempt to force glue sticks or spray into or through the gun can actually damage the feeding mechanism.

Building the proper amount of warm-up time into your operating procedure can reduce issues with glue adhesion and help protect your glue gun from stress or breakage where the glue is fed in.

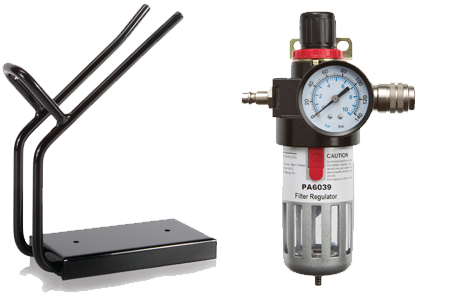

2. Keep the glue gun standing upright.

All industrial Tec glue guns come with a tool stand that can be attached to a workstation. This allows you to set the gun upright while it is powered up but not in use. You can also use another type of portable glue gun stand or a suspension hook to keep the glue gun upright, but it's important to do so.

Putting a hot glue gun on its side can cause the adhesive to leak into areas where it should not be. The glue may leak excessively from the tip when you pick it back up or pool inside the glue gun. You risk either getting a burn, damaging the interior of the tool or both.

3. Never remove the nozzle from a cold applicator.

Taking the nozzle off of a glue gun should only be done when the tool is warm. You can give the glue gun a minute or two after powering it off, but don't let it get cool. If you try to remove the nozzle from a cold glue gun, you could damage the threading system and make it difficult or impossible to easily switch out nozzles in the future.

To remove a nozzle, you should wear protective gloves, as the adhesive applicator and nozzle can cause burns to bare skin. Make sure the applicator is free from adhesives and gently unscrew the nozzle. Place your new nozzle on the applicator and tighten. Don't forget to clean your original nozzle before putting it away.

4. Unplug the glue gun if it will be idle for 40 minutes.

You don't want the glue gun to sit with hot adhesives for an extended period. A good rule of thumb is to unplug the tool completely if you won't be using it for 40 minutes.

The reason? Tec glue guns have pre-set heaters that constantly melt the adhesive so you get a uniform dispersion of adhesive. But when you aren't moving the hot adhesive through the gun, it can actually get too hot. That can result in glue that is charred or won't work as it should, or worse, a blocked nozzle. In some glue gun models, overheated adhesive can actually back up in the chamber, and when you pick the tool up, you are at risk of getting burned.

5. Pass the remainder of your glue stick through the chamber after the gun is powered down.

You'll find it easier to use your Tec glue gun if it is clean and ready to use when you need it. So to ensure you can easily start the gun back up, take a few seconds after you disconnect the tool from power to extrude molten glue out of the glue gun. This should be done while the tool is cooling, but not once it is actually cool.

After extruding the adhesive, wipe down the nozzle to make sure that no glue remains to build up and potentially char the next time you use the glue gun.

You'll find that you will need to move about a stick or half cartridge of glue through to get the glue gun ready for next time. Factor this use of glue into your estimates of how much adhesive you'll need for your industrial needs. Remember never to pull a glue stick back out of the glue gun, as this can damage the feeding mechanism.

In addition to following these tips for best practices in using your glue gun, consult your Tec manual for complete operating instructions.

If you have questions about Tec glue guns and which model or models are right for your industrial needs, please contact us.