Whether you’re new to the world of glue guns or consider yourself to be a bit of an expert, it never hurts to get a little advice before making a purchase. Thanks to glue guns, manufacturers and crafters everywhere no longer have to break out a hammer and nails for every project.

Glue guns allow you to enjoy long-lasting results that are aesthetically pleasing. Imagine enjoying the strength of several nails holding your furniture together, simply by using a viscous liquid. Not only is the bond invisible, but it's also less likely to poke out and cause an injury.

Still, just as not all projects are made equal, neither are all glue guns. If you’re considering the differences between Power Adhesives guns, pneumatic glue guns, and cool glue guns, understanding how they operate will help you choose a device that’s perfect for your project.

Power Adhesives

If you’re in need of a glue gun that’ll produce results that are resistant to heat and chemicals, you’ll need a Power Adhesive glue gun. They produce hot glue, which then solidifies to form a firm seal that’s difficult to break through.

Common applications for these guns include:

- Woodwork and assembling furniture.

- Retail manufacturing, such as putting products together.

- Recreational décor, such as baseboards.

- Shipment and packaging that requires a firm seal that will allow goods to remain in place during transit.

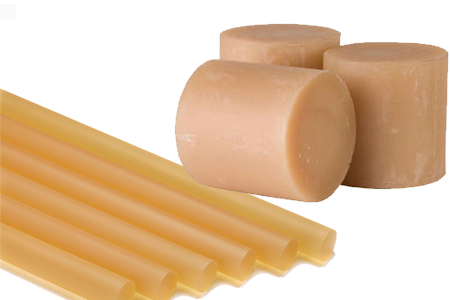

It’s important to understand, there are several different products available and the one you need depends on your operations. Many of these guns are color-coded so you can match the color to its application.

They also come with nozzles that allow for accuracy. This means they’re especially useful if you’re aiming for precise results. The glue melting process takes two to five minutes and is regulated, so it’s neither too hot nor cold. As such, your efforts are both precise and swift.

It’s worth noting that the metal components that heat the glue are extremely hot, but they’re encased in a plastic that’s designed to prevent burns. When selecting your product, you may want to pay attention to the temperature specifications:

- A gun producing temperatures of 250 degrees or more is ideal for delicate materials.

- Guns that extend beyond 400 degrees are better for more robust or hard materials.

Pneumatic Spray Gun

If you’re seeking exact results, and you want to ensure your gun delivers the same amount of glue each time the trigger is pressed, you might want to consider using a pneumatic spray gun. Typically used for larger operations, pneumatic spray guns come with extra high wattage, which allows for large volumes of glue to be heated each time you press the piston.

As they heat high volumes of glue, these guns are great for tougher materials on large production lines. Many also come with an adjustment nozzle that you can set to deliver a specific amount of glue as you press the trigger. One of the key benefits of this is that you have uniform results, which is especially handy when you’re working in industries such as furniture manufacturing.

Pneumatic glue guns are ideal for a range of processes including:

- Repairing items around the house, such as hardwood flooring

- Piecing furniture back together

Many of these guns are large, so you might be forgiven for thinking you’d struggle to hold them for long periods. Fortunately, many also come with balancers. Balancers are designed to take the weight from the gun and hold it in place, making it possible for you to proceed with your manufacturing processes without tiring yourself out.

Some pneumatic glue guns come with foot pedals. This takes the strain away from your fingers and allows you to maintain your dexterity when assembling parts, making the manufacturing process simpler. One example of this is the Tec 7300 Multi-load pneumatic spray gun. In addition to featuring a balancer, it’s useful for sensitive materials because it’s possible to use it at lower temperatures than other guns.

Low-Temperature Glue Gun

It’s important to understand that a low temp glue gun doesn’t shoot the glue out at ice-cold temperatures. They’re still at around 200-250 F, making them slightly cooler than some of their hot gun counterparts.

So, why would you want to choose a cool glue gun? Some materials tend to crumble under high temperatures because they just can’t handle the heat. This includes paper, foam, and cardboard. They reduce the risk of operator burns, which is a massive benefit for your risk assessment processes. However, although these burns won’t result in you or your employees ending your shift in the emergency room, the burn won’t be pleasant, so it’s still important to exercise caution.

Surprisingly, even though they don’t deliver high temperatures, they can lead to greater joint stability and flexibility. This means you don’t risk damaging the sensitive materials you’re using for your project, but your item’s components remain stable, nonetheless.