Hot melt is the name given to any polymer-based glue that is applied in a molten state. The application of the adhesive is usually by an industrial glue gun, which works through either trigger action or finger pressure. Hot melt is used in a variety of settings due to its versatility, including packaging, bookbinding, carton-making, graphic arts, tapes and labels, product assembly and in the automotive industry.

Hot melt is appealing for many reasons. For one, it is fast-acting. In fact, the time to cure, or set, can be adjusted based on the needs of the job. Hot melt is safe to use and environmentally friendly. In addition to bonding difficult surfaces, hot melt can also be used to fill gaps. It is also easy to ship and store.

Advantage of Hot Melt over Solvents

Hot melt has become so popular that is it overtaking solvent-based adhesives. Solvent-based adhesives are mixtures of various ingredients dissolved in a solvent. When the solvent evaporates, the material sticks. Hot melt, which is polymer-based, gets around many of the problems with solvent-based glues.

Hot melt is faster, more cost-effective, more adhesive, and produces much less volatile organic compounds than solvent-based adhesives.

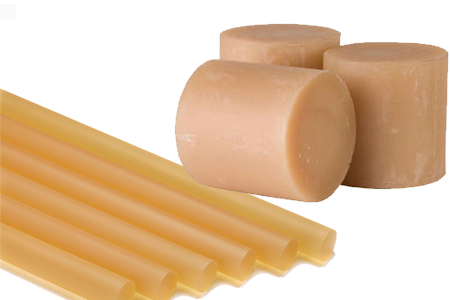

Due to its chemical nature, hot melt can come in any number of forms. This includes glue sticks, pellets, bags, cakes, drums, bricks, slats, and pillows. Hot melt can also be applied in several ways, including through nozzles, extrusion, melt blowing, spiral spraying, screen printing and slot die coating. The dispensing equipment for hot melt can come in the form of melt reservoirs, vacuum conveyance, drum or pail unloaders, and pre-melters.

Raw Materials

The raw materials used in hot melt affect its function, cost, availability, and performance. In general, hot melt is composed of a polymer (which can come in various forms) and several additives. These additives include resins, waxes, antioxidants, and plasticizers. Other chemicals can be added to give hot melt more properties.

Polymers. The basic constituents of hot melts (and many types of glue) are polymers. These are long, repetitive chains of certain molecules that have different properties based on the length of the chains and the type of the molecule.

The primary polymers used in hot melts are ethylene-vinyl acetate (EVA), polyolefins, polyamides and polyesters, styrene block copolymers, polyethylene, and ethylene-methyl acrylate (EMA) or ethylene n-butyl acrylate (EnBA).

Polymers give hot melt its strength and flexibility, heat resistance, impact resistance, and shear. These characteristics are guided largely by the type of polymer, its molecular weight, and its amount.

With greater polymer content, you get a higher viscosity (which is a measure of the thickness of a liquid), and greater flexibility and toughness. With lower polymer content, there is lower viscosity.

Tackifying resins. Resins define the tack of hot melt. Tack is the measure of the stickiness of an adhesive, essentially how long the adhesive stays stuck after it is applied. Resins, therefore, control the wetting of an adhesive (i.e., how long it remains a liquid while in contact with the substrate surface).

Resins also have an influence on the adhesive nature of the hot melt. The choice of resin is determined by its compatibility with the main polymer, its softening point, and the specific adhesion. The primary types of tackifying resin used in hot melt are rosin and hydrogenated rosin, C9, hydrogenated hydrocarbon, terpene phenolics, rosin ester, and C5. Pure aromatic monomers are also used.

With more tackifying resin, you get a hot melt with reduced tack and faster speed. With less tackifying resin, you get a tougher, more aggressive hot melt.

Waxes. Wax in hot melt primarily controls the set speed and open time. The open time is the amount of time it takes to make a bond. This can range from a few seconds to an endless duration (for some pressure-sensitive hot melts). The set speed measures how quickly the hot melt can form a bond of some acceptable strength.

These two values have to match parameters used in production lines exactly. In addition to set speed and open time, wax also influences the heat resistance and sub-ambient (i.e., below application temperature) adhesion of hot melt.

The main types of wax used in a hot melt are, natural waxes, microcrystalline waxes, and synthetic waxes. The characteristics of the wax are determined by the percent of crystallinity, melting point, and molecular weight.

The main types of wax used in a hot melt are, natural waxes, microcrystalline waxes, and synthetic waxes. The characteristics of the wax are determined by the percent of crystallinity, melting point, and molecular weight.

With lower wax content, the hot melt will have higher viscosity and greater flexibility, and will bond more aggressively. With less wax, the hot melt will have a lower viscosity, set faster, and bond less aggressively.

Antioxidants. Antioxidants are used in hot melts primarily to protect the material from degradation over the period of its shelf life. Some of the commonly used antioxidants in hot melt include phenols, aromatic amines, phosphates, phosphites, and BHT.

Along with stabilizers, antioxidants are added in small amounts and do not influence the physical properties of the hot melt. They protect the hot melt not only during its shelf life but also during its molten state when it is being applied and when it is being compounded.

Plasticizers. Besides the base polymer and tackifying resin, plasticizers are the most common additive in hot melt. In fact, they are used as a sort of second base polymer to give the hot melt greater flexibility and toughness. Plasticizers are often hydrocarbon oils that are low in aromatic content and which have the chemical characteristics of paraffin.

Ideally, the plasticizer has a low volatility, is transparent, and has no odor. Using a plasticizer, a hot melt can achieve a lower melt viscosity and wet faster.

Bio-Based Materials. More recently, there has been a new development in hot melt composition with a product that is 45% bio-based and certified biodegradable to ASTM D6400 standards. These biodegradable glue gun sticks are designed to fully break down into non-toxic components.

In addition to these main ingredients, hot melt comes with several other additives to give it certain desired characteristics. Biocides prevent bacterial growth while fillers add bulk and strength while reducing cost. Hot melt can also come with flame retardants and various pigments or even glitter.

Critical Adhesive Properties of Hot Melt

The main defining characteristics of hot melt are its viscosity, molten color, failure temperature (for shear adhesion and peel adhesion), softening point, substrate specific adhesion, thermal stability, cold crack formation, loop tack, and various mechanical properties.

Viscosity. Viscosity is the measure of the thickness of a liquid or how much it resists flow. High viscosity liquids move very slowly (think of oil). Higher viscosity liquids, like water, flow more easily. The viscosity of hot melt is not just a single value but depends on the application temperature (which can range from 250 to 350 degrees Fahrenheit).

It is also important to know the shear rate (or the rate at which a layer of fluid changes velocity when it is traveling over an adjacent surface) to figure out viscosity.

There are various devices used to test the viscosity of hot melt. These include the Brookfield Thermosel (for low shear), Dynamic Mechanical Analysis (for low and high shear) and the capillary rheometer (for high and very high shear). The unit for viscosity is the poise.

Molten color. The color of hot melt is measured on a numerical scale using both subjective and quantitative methods. These include the Gardner, Hunter, and Saybolt methods and the Yellowness index.

Peel. Peel is the measure of how much force you need to break the bond between two bonded surfaces. Peel is expressed in pounds per inch and can be measured at different angles (right angles and 180 degrees are the most common) and for different surfaces.

Failure temperature. As the name implies, the failure temperature is the temperature at which the hot melt stops working. There are two kinds of failure temperature measurements used to characterize hot melt.

Failure temperature. As the name implies, the failure temperature is the temperature at which the hot melt stops working. There are two kinds of failure temperature measurements used to characterize hot melt.

Peel Adhesion Failure Temperature. At greater temperatures, it becomes easier to peel away two surfaces bonded with hot melt. The PAFT measures how much the hot melt can resist peeling at higher temperatures. In the test, the temperature starts at 25 degrees Celsius and increases at a rate of 25 degrees per hour. The weight applied to induce peeling is 100 grams for a 1-in x 1-in x 0.01-in sample.

Shear Adhesion Failure Temperature. Shear is a force that exists as one surface slides over another. In a shear test, a specimen is vertically mounted and a weight attached. How long it takes for the surfaces to detach from each other tells you how strong the hot melt is. SAFT is measured the same way as PAFT but with shear instead of peeling. The temperatures are the same, but the weight is 500 gm.

Softening point. The softening point of hot melt (or any glue) is the temperature at which the glue starts flowing. The primary determinants of hot melt’s softening point are the melting point of the wax being used or the transition temperature of the base polymer (in the case of styrene block copolymer-based hot melt). The ring-and-ball and Mettler methods are commonly used to measure SP.

Substrate-specific adhesion. This measure depends on what kind of material you are attempting to use the hot melt for. Characteristics such as bond strength can be determined using actual substrates. You can also test the property at different temperatures (ambient, sub-ambient, and elevated).

Thermal stability. How stable hot melt is under different temperature changes tells you how durable it will be overall. For the thermal stability test, you heat the hot melt to its pot temperature (the temperature at which it would boil if in a liquid form). Hot melts with good pot stability do not char or decompose at higher temperatures.

Using the thermal stability test, you can determine the change in viscosity, any changes in color, the formation of charring, edge rings, skin, and gel.

Cold crack formation. At the other end of the temperature spectrum, some hot melts tend to crack. Tests are used to determine at what low-temperature cracking occurs. For EVA-based hot melts, temperatures between 45 and 15 degrees Fahrenheit are used. For rubber-based hot melts, temperatures between 30 and 10 degrees are used.

Cold crack formation is important to study, especially in graphic arts application. This is because you can see how flexible a book spine will be at colder temperatures.

Loop tack. Loop tack is a measure used only for pressure-sensitive hot melts (i.e., hot melts which form bonds when pressure is applied). Loop tack measures the “aggressiveness” of a hot melt, normally in ounces. If you need a higher force to pull a hot melt, then it is more aggressive (sticks harder).

Mechanical Properties. There are various mechanical properties that are relevant to hot melt. These include tensile strength (how much force you need to apply to break a sample), yield point (how much stress you can apply to hot melt before it deforms permanently), elongation at break (how long a specimen will stretch before breaking), and Young’s modulus (stress over strain ratio). Other properties are combinations of these.

In some cases, cold adhesives are desired. This is especially true when the substrate is highly temperature sensitive. In these cases, a water-based adhesive is advised.

Function, Performance, Cost

The different materials used to make hot melts and the resulting properties of the adhesive mean there is a great diversity in the function, performance, and cost of hot melt products.

Tapes and labeling hot melts. The kind of hot melt used for tapes and labels are typically pressure-sensitive. For labeling, you need products that are customizable, can be die-cut, and which offer a range of tack levels. For tapes, you can use a smaller tack range, but you need a high level of shear resistance.

Pressure-sensitive hot melts are beginning to replace solvent-based ones, partly because they offer better heat and plasticizer resistance.

Packaging hot melts. Hot melts are used in various forms of packaging, including case-, carton-, and heat sealing; tray forming; and container labeling. The key performance characteristics of packaging hot melts are their versatility when it comes to adhesion; their increased pot life (aging performance of hot melt adhesives); and their lower odor, cost, and application temperature.

The optimal packaging hot melt has the following properties: 900 cps viscosity (at 350 degrees Fahrenheit), 1-2 second set speed, 3-4 second open time, a PAFT of 135 degrees Fahrenheit, and a SAFT of 200 degrees Fahrenheit.

A special case of packaging hot melts—heat seal hot melts—is used for flexible packages (e.g., lids and small containers), carpets, and in vehicles. In the heat sealing process, hot melt is applied to one surface, and that surface is then wedded to another one, after which heat and pressure are applied.

Graphics arts hot melts. Hot melts used in graphics are normally EVA-based and applied at between 325 and 350 degrees Fahrenheit. They are fast-setting and perform well anywhere between 20 and 120 degrees Fahrenheit. Graphics hot melts also possess lay-flat (or mouse trap index) characteristics, which means they do not snap shut when released. They are also resistant to ink solvents.

The application of hot melt is a delicate matter and a range of tools is available to accomplish this end, the gun being the most commonly used. Even given the same gun, there is flexibility in how the hot melt can be applied, with a selection of nozzles, for example.

Hot Melts Are Everywhere

Due to their unique characteristics and flexibility, hot melt adhesives are used in a wide variety of settings. The packaging, graphics, automotive, converting, and many other industries have been affected. As polymer technology gets more advanced, we can hope to see an even greater range of applicability. Hot melts are increasingly being made to be specific to individual substrates.