Table of Contents

- Why Pallet Transit Damage Happens

- How to Secure a Pallet for Shipping to Minimize Damage

- Adhesive Stabilization Solutions

- FAQs

Pallet transit damage is a common and costly problem for businesses when it comes to distributing their goods. Before a pallet even reaches its destination, it can be deformed, torn, scratched, or crushed. In some cases, the damage can be so bad that the product is no longer usable or fails inspection. For businesses, these are huge losses that many cannot afford.

Our team works with manufacturers and businesses that struggle with damaged pallets during shipping. The good news is that you can take steps to reduce pallet damage during shipping. In this guide, our team shares some tips on how to palletize for shipping as well as some of the best solutions to minimize shipping damage for pallet transit.

Why Pallet Transit Damage Happens

Although a pallet load may look fine when it is first sent on its way, it can easily end up destroyed by the time it reaches its final destination. Damage to pallet loads is often the result of a cumulation of events. In many cases, the damage builds over time during transport because of vibrations, braking, sharp turns, or repeated handling. Before diving into solutions for pallet protection, it helps to understand the causes of pallet damage during transit.

Some common causes of pallet load damage during transit include:

- Uneven weight distribution

- Weak, damaged, or compromised wood pallets

- Pallet overhang

- Insufficient or excessive stretch wrap tension

- Insufficient or improper stabilization material usage

- Excessive movement or shock during transport

- Rough or excessive handling

- Inspections that break down and open the pallets

When these factors stack up, even well-wrapped and packed pallets can become unstable and experience damage.

How to Secure a Pallet for Shipping to Minimize Damage

Protecting pallets during shipping is more involved than just stacking some boxes and wrapping them in plastic stretch wrap. Every mile of transit can expose the pallet to conditions that can damage the load. But following the right protocols and using the right materials can help you significantly reduce the risk of damage.

Our team shares a few tips on how to palletize for shipping to decrease damage during transit and keep your goods in good shape all the way to their destination.

Start With the Right Pallet and Load Design

A stable pallet load starts with the pallet board and the way the goods are loaded. The pallet itself should be in good condition as a damaged pallet board can create an unstable base for the loaded pallet. Once you have a board in good condition, it is important to understand how to pallet items for shipping to minimize potential damage. Loading the pallet should focus on proper stacking and weight distribution of the goods themselves.

Some best practices on how to load a pallet for transit include:

- Following weight restrictions

- Avoiding pallet overhang

- Distributing weight evenly across the pallet board

- Using a layered approach to packing

- Placing the heaviest items on the bottom when applicable

Improper loading can lead to pallet damage regardless of how well the pallet is packed.

Add Internal Stabilization Between Layers

When using a layered approach to packing, it is important to stabilize the load internally with the right materials. Fill gaps with dunnage. Traditionally, many manufacturers use anti-slip paper or cardboard sheets between layers, but pallet stabilization adhesives are a growing solution that can be a more sustainable option than plastic wrap alone.

Pallet stabilization adhesives are designed to create a temporary bond that creates friction to hold pallet load layers in place during transit but offers a clean release at depalletization. They are often applied in patterns between cases as the pallet is built.

Apply External Containment

To ensure your pallet survives transit, use the correct stabilization materials on the exterior and wrap the pallet for shipping correctly. Stretch wrap, corner boards, or strapping are essential to reinforce pallet loads and prevent movement or damage during transit. These materials protect the load and help it stay intact, but they work best when the load is already stable internally.

Verify Stability Before Shipping

After you pack a pallet for shipping, you should perform a stability check before it leaves your dock. Inspect the pallet load for visible movement, leaning, pinching, or gaps. This quick check can help you catch issues and fix them before they lead to damaged goods.

Adhesive Stabilization Solutions We Recommend

Load damage is often tied back to insufficient friction between pallet layers. Applied in the right way, pallet stabilization adhesives can be an effective solution to prepare a pallet for shipping and prevent pallet damage during transit. Since we have been in the adhesives industry for over fifty years, we are sharing a few pallet adhesives to protect a pallet during transit.

For Bulk Applications

The Breakaway pallet load stabilization system includes a water-based pallet adhesive and its application equipment. The equipment can be easily incorporated into your existing production process, so as cases, bags, or boxes pass, a small amount of the adhesive is applied before it is stacked onto the pallet. The adhesive is also designed to come off cleanly to avoid damage to the products. This full system is ideal for high-speed and high-production lines.

You can even demo the equipment in your facility before purchasing. Learn More.

For Manual Applications

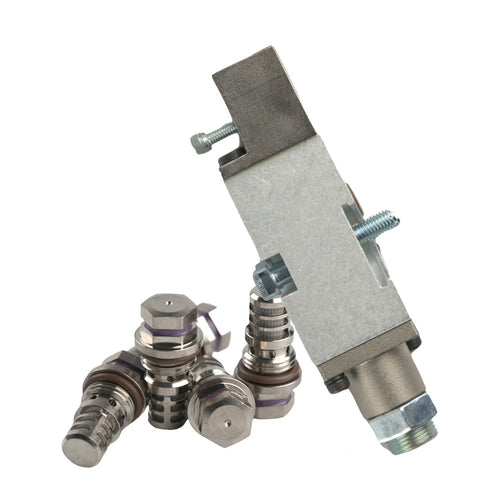

If you are looking to palletize a shipment for transit but have smaller volume needs, a manual option is the Tecbond 410 pallet stabilization adhesive. This hot melt comes in sprayable slugs that can be applied with a Power Adhesives pneumatic applicator. It works in the same basic way as the Breakaway adhesive system but does not require the extensive equipment.

Get Started

Now that you know more about how to palletize for shipping, you may be interested in incorporating a pallet stabilization adhesive into your production process. We want to help. Contact us to speak with our staff about your production needs and we will recommend a solution for you.