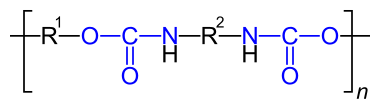

About Polyurethane

Polyurethane, or PUR, is a synthetic material made up of many organic units connected by urethane links. It is classified as a polymer because it has a molecular structure made up of similar units in a repeating chain.

Invented in the 1930s, PUR was first used as a cheaper alternative to costly rubber during World War II. Over time, other PUR applications were developed. Today, they PUR has numerous applications including everything from airplane finishes to insulation and adhesives.

PUR Adhesives

Using PUR in adhesives is a relatively recent development. Introduced in the 1990s, PUR hot melts are often used in packaging, woodworking and shoes. They are highly flexible and can withstand a broad range of thermal settings, making them ideal for hard-to-bind substrates.

PUR hot melt adhesives are significantly stronger than traditional hot melt adhesives. They can provide adhesive strengths greater than 1,000 lbs. This is because PUR polymerizes when it comes into contact with the moisture in the air, allowing it to form stronger bonds after the curing process is complete.

PUR hot melt adhesives are significantly stronger than traditional hot melt adhesives. They can provide adhesive strengths greater than 1,000 lbs. This is because PUR polymerizes when it comes into contact with the moisture in the air, allowing it to form stronger bonds after the curing process is complete.

In edge splice tests performed on composite wood panels by 3M, the wood substrate fractured under pressure while the PUR bond line stayed intact. This proved the superiority in the strength of PUR adhesives.

Additionally, PUR hot melt has a low volatile organic compound (VOC) content compared to traditional hot melt materials. Since many VOCs are hazardous air pollutants, having a low VOC count makes PUR adhesives the environmentally friendlier option. The need for having drying and ventilation equipment on site after the adhesive is applied can also be eliminated by using PUR hot melt.

Some PUR hot melt adhesives have fast set times and can form strong initial bonds in as little as 15 seconds. Most PUR adhesives also require 24 hours before they are completely cured, and during this time their strength continues to increase from reactions with the moisture in the air. This means it is very important to expose the PUR adhesive to air once it is applied.

The Right PUR Applicator

Care should be taken when selecting the right applicator, as PUR hot melt adhesives come in both high and low-temperature versions. The PUR adhesive also cannot be exposed to air before application to prevent premature curing. This means a standard hot melt gun cannot be used to dispense PUR hot melts, and you will need a special cartridge or applicator designed specifically for PUR hot melts.

A popular PUR hot melt applicator is the 3M Easy 250. This is an industrial-use, self-contained applicator specifically designed to dispense PUR hot melt adhesives at 250°F. You can also use it with any brand of PUR adhesives.

The 3M Easy 250 is UL tested and rated to meet North American safety standards and can hold hot melts at dispensing temperatures for up to 16 hours at a time. It comes with a plastic disposable tip that can be replaced when worn.

Another popular PUR hot melt applicator is the Infinity PUR Hot Melt Cartridge Gun by Infinity Bond. This applicator dispenses 50 grams of hot melt at a time and only works with Titebond HiPURformer or Infinity PUR cartridges. However, it offers the ease of wireless dispensing by providing a heating station which warms up hot melts within 5 to 10 minutes.

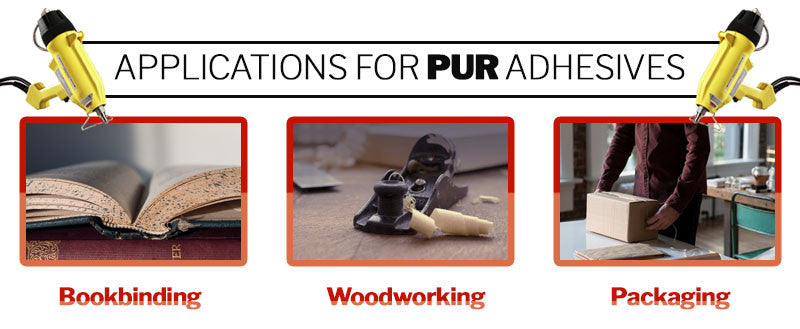

Applications for PUR Adhesives

PUR adhesives are ideal for working with difficult substrates that require some degree of elasticity.

Bookbinding

Using PUR for binding books eliminates any initial fixturing of the pages. The PUR hot melt also increases the book’s pull and flex strength, making books more durable and allowing them to lie flat without wrinkling the spine. This means readers can bend the pages without breaking apart the spine.

Woodworking

PUR adhesives are an excellent choice for woodworking and other construction applications. They provide the high strength required to hold the construction materials together. For example, using PUR adhesives to assemble wood furniture eliminates the need for screws and nails. This means the overall aesthetic contour of the wood furniture is preserved while the time and effort required to drill holes for the nails are eliminated. Other PUR adhesive woodwork applications include decorative molding, edge-to-end grain wood adhesion, and countertop edging installations.

PUR adhesives are an excellent choice for woodworking and other construction applications. They provide the high strength required to hold the construction materials together. For example, using PUR adhesives to assemble wood furniture eliminates the need for screws and nails. This means the overall aesthetic contour of the wood furniture is preserved while the time and effort required to drill holes for the nails are eliminated. Other PUR adhesive woodwork applications include decorative molding, edge-to-end grain wood adhesion, and countertop edging installations.

Packaging

Just like EVA hot melts, PUR hot melts are an excellent choice for carton closing, sealing and pallet stabilization. However, PUR offers a stronger adhesion and cures better than traditional hot melts, making it a desirable alternative in the demanding industrial packaging industry. Additionally, PUR adhesives are available in clear versions, making it easy to hide any glue lines to give an appearance of continuity in the material.

Working with PUR Adhesives

Due to the special nature of PUR materials, care should be taken when using and storing PUR hot melts.

Shelf Life

You can prolong the shelf life of PUR adhesives by storing them in a foil pouch in a cool, dry location. Special care should be taken to not expose any PUR tubes to moisture.

At the end of your work day, extrude a 1-inch bead of adhesive to ensure all the air has been extracted from the tube, effectively keeping it preserved. You can also use a purge cleaner to prevent the PUR from hardening inside the nozzle. Most PUR cartridges also provide detailed instructions on how to properly store the product inside.

Safety

When working with PUR hot melts, always make sure you have on personal protective equipment, especially gloves and safety glasses. This is to ensure the PUR hot melt will not come into contact with your skin or eyes, as their rapid setting times mean it will be very difficult to get them off your skin. Additionally, you should never touch the applicator’s heat cylinder or cartridge when you are working, and do not apply PUR hot melts onto heat-sensitive materials.

Test Area

You should always test your choice of hot melt adhesives before the start of any project. Whether you’re using PUR another type of adhesive, you should first apply the hot melt on a small, inconspicuous area and wait for it to cure completely before applying it to the entirety of your project. You can do this on a scrap piece of material or apply the adhesive to a portion of your project that’s well-concealed.

Choosing the Right PUR Hot Melt

Although all PUR adhesives share similar qualities, you will want to consider material, temperature, curing time, viscosity, cost and other factors, such as flexibility.

3M and Titebond are two of the biggest names when it comes to PUR hot melts. Titebond is a company specializing in adhesives and sealants, whereas 3M is a multinational conglomerate that produces everything from hot melts to medical products. Both can be trusted to produce high-quality hot melts.

3M and Titebond are two of the biggest names when it comes to PUR hot melts. Titebond is a company specializing in adhesives and sealants, whereas 3M is a multinational conglomerate that produces everything from hot melts to medical products. Both can be trusted to produce high-quality hot melts.

A popular line of hot melts by 3M is the Scotcht-Weld Adhesive Series. This line of PUR hot melt features a range of set times starting from 15 seconds to 2.5 minutes. Each product in this series also has a different viscosity and tensile strength, and each will work with a variety of materials ranging from leather to nylon and PVC.

The success of your project depends on choosing the right materials for the job. For hot melts, this means choosing the right one to match the material you are working with. For example, the TE-015 hot melt in 3M’s Jet-Weld Adhesives series has a set time of 15 seconds and is ideal for fabrics, leathers, and wood.

The TE-040, on the other hand, has a set time of 40 seconds and also works well on fabrics and leathers, but with the addition of glass, aluminum, and polystyrene. Both hot melts have a viscosity of 7000 cps, but the TE-040 will not work as well as the TE-015 on wood surfaces.

High vs. Low-Temperature

For most projects, you can use hot melts with higher application temperatures for materials such as wood, metal, and heavy cardboards. This is because these materials are quite hardy and can withstand higher temperatures. For more delicate materials such as fabrics, foam, and papers, you will want to choose hot melts with lower application temperatures to avoid damaging the material. Check out our helpful hot melt temperature guide to learn more.

Set Time

Set Time

Set time is the time required for the hot melt to become rigid and gain partial strength. It is different from curing time as the curing time is how long it takes for the hot melt to become completely dry and obtain its full strength.

As we’ve discussed, most PUR hot melts generally have a longer curing time than other types of hot melt adhesives. However, these PUR hot melts make up for this longer curing time by having faster setting times.

Specifically, 3M’s Scotch-Weld PUR series offers hot melts with set times ranging from 5 seconds to 2.5 minutes. This difference in set times is used to accommodate the types of materials being used. For example, the EZ250015 has a set time of 15 seconds and is designed for wood and some plastic materials. The EZ250120, on the other hand, has a longer set time of 2 minutes and is designed to make thin bond lines on wood, making it ideal for gluing wooden pieces together to look like a single continuous piece.

Viscosity

In material science, viscosity is defined as the resistance of a fluid to flow through a certain orifice. It is measured in pascal seconds, which is also known as centipoise, or cps for short. In PUR hot melts adhesives, the orifice from which flow is measured is typically the applicator or the nozzle.

Hot melts can be described as having low, medium, or high viscosity. In material science, fluids with low viscosity are thinner with a faster flow rate than fluids with high viscosities. For example, honey can be classified as a fluid with a higher viscosity than water, since honey is thicker and will not flow as fast as water.

When considering hot melt viscosities for practical applications, you will want a thicker viscosity hot melt for projects where gap-fillings or assembly are involved. In packaging, however, using a hot melt with a thinner viscosity is ideal.

Cartridge vs. Hot Melt Guns

PUR hot melt can be applied in a number of ways, with the most common being the self-contained PUR cartridge, which keeps the glue at optimum temperature and protects it from air exposure until it’s time for use.

You may also use a PUR hot melt applicator such as the 3M Easy 250 PUR Hot Melt Applicator to dispense standard PUR adhesives. We recommend investing in a hot melt applicator if you intend on using PUR guns in industrial or heavy-duty applications. For casual and occasional use, purchasing a cartridge is a great choice.

Other Features

PUR adhesives by 3M and Titebond can also be formulated with special properties, such as having a higher level of flexibility, better application temperature heat stability or having very thick or thin glue lines. Some PUR cartridges are even equipped with a UV indicator for quality control and to ensure that the adhesive has not been compromised before use.

Need Help Finding the Right PUR Hot Melt?

Choosing the right PUR hot melt for your job can be challenging. If you follow these best practice tips, do your research beforehand and use a knowledgeable and experienced vendor, you will be well on your way to enjoying the benefits of PUR hot melts.

Related Products: Infinity Bond Flex 50 PUR Hot Melt Applicator

Set Time

Set Time