APAO Hot Melt Adhesives - The Basics

Adhesives are everywhere and APAO hot melt is no exception. This unique bulk hot melt chemistry is used in applications ranging from specialty packaging to automotive assembly and everything in-between. This article aims to demystify APAO hot melt and help users better understand the applications where these type of adhesives excel.

The Technical Stuff

APAO hot melt stands for Amorphous Poly Alpha Olefin. With a name like that, you can understand why the industry simply calls it APAO. The Olefin polymers that make up this type of adhesive are produced from Propylene, Ethylene and/or Butene-1 which along with a catalyst system, give it the characteristics to adapt and be used in a wide range of applications. If none of that made sense, don’t worry, we’ll break it down as we go. If it did make sense, congratulations on your impressive chemistry skills, might be time to apply for a spot on Jeopardy.

Types of APAO Hot Melt: Homopolymers, Copolymers and Formulated

APAO hot melts can be formulated (mixed with more common hot melt ingredients) or they can be used ‘as-is’ in a few different forms. Formulated hot melts are typically more expensive as they use more ingredients and can cost more to manufacture.

Homopolymers

Homopolymers are APAO in its truest form. They are made up of 100% propylene.

Characteristics of Homopolymers

Homopolymers offer exceptional heat resistance, are very hard and have fast set times. Homopolymers are used to replace the more expensive Polyamide hot melt adhesives in many applications.

- Excellent Heat Resistance

- Cured Product is Very Hard

- Fast Set Times - Low Stringing on High Speed Lines

Copolymers

Copolymers are a combination of polypropylene and either Ethylene or Butene-1. The different combinations and ratios of these three raw materials will change the end products open time, heat resistance, bond strengths and hardness.

Characteristics of Copolymers

- High and Low Temperature Resistance

- Hardness ranges from medium to soft

- Open times can range from medium to very long

- Products can be used in hot melt spray applications

- Offers strong bonds to a wide range of substrates

Formulated

Formulated APAO is a combination of everything above along with more traditional hot melt ingredients allowing for very specific bonding characteristics and attributes.

Characteristics of Formulated APAO’s

- Specific characteristics can be accentuated (like cold resistance, softening point, open time, etc)

- Can be formulated to bond specific or very difficult substrates

General Benefits of APAO Hot Melt

APAO hot melts offer a number of advantages over traditional hot melt adhesives and other adhesive chemistries. We’ve covered a lot of them in the previous section but here are the reasons we love APAO’s.

- Excellent heat resistance: can often replace polyamide hot melt, structural adhesives or other more expensive and difficult to dispense adhesive.

- Excellent cold resistance: with copolymers and formulated products

- Low cost: can often replace higher price hot melts and other adhesive chemistries 10X as expensive

- Long open times available - can be dispensed as bead or spray

- Strong bonds to a wide range of substrates

- Can often replace polyamide hot melt, structural adhesives or other more expensive and difficult to dispense products

Applications for APAO Hot Melt

APAO hot melts are used in a huge range of applications and really excel in product assembly environments. Below is a list of common applications and we continue our series on APAO adhesives, we’ll dig into each of these applications more in-depth.

General Purpose Product Assembly APAO Hot Melts

Product assembly is a general term that covers a wide range of manufacturing efforts across a huge range of industries. APAO hot melts in general offer exceptional bond strength and temperature resistance so they are excellent performers in assembling and manufacturing. Key differences in high performance APAO adhesives will be the set time.

Below is a list of top product assembly options that cater to a range of open time needs. These would be the 'go-to' for strong bonds, easy dispensing and middle of the road characteristics like viscosity and hardness.

- Infinity Bond IM-A6270 - 5 Second Open Time APAO Hot Melt

- Infinity Bond IM-A6060 - 20 Second Open Time APAO Hot Melt

- Infinity Bond IM-A6040 - 60 Second Open Time APAO Hot Melt

- Infinity Bond IM-A6250 - 120 Second Open Time APAO Hot Melt

- Infinity Bond IM-A6290 - 300 Second Open Time APAO Hot Melt

Automotive Assembly and APAO Hot Melts

APAO hot melts are used in many facets of automotive assembly and found in hundreds of thousands of cars on the roads today. Common automotive uses for APAO hot melt adhesives include:

- Battery assembly

- Bonding foam to foam

- Load Floors

- Automotive Filters

- Headliner component assembly

- Head lamp bonding

- HVAC assembly

- Sound deadening

- Bi-laminate fabric on door and instrument panels

Why APAO Adhesives Excel in Automotive

- Inherent moisture resistance

- Good UV stability

- Functionality over wide range of temperatures

- Flexible open time

- Excellent thermal stability

- Allows for rework

- Amorphous vs. other crystalline alternatives

Popular APAO Hot Melts for Automotive

Automotive Battery Assembly

- Infinity Bond A6110 APAO Bulk Hot Melt

- Infinity Bond A6080 APAO Bulk Hot Melt

Sound Deadening, Load Floor and Foam Bonding

- Infinity Bond A6290 APAO Bulk Hot Melt

- Infinity Bond A6300 APAO Bulk Hot Melt

Headliners, Head Lamp Bonding, Vibration/Sound Deadening

- Infinity Bond A6030 APAO Bulk Hot Melt

Fabric, Panel and Load Floor Bonding

- Infinity Bond IM-A6060 APAO Bulk Hot Melt

Furniture Manufacturing and APAO Hot Melts

Furniture manufacturing is a huge industry that covers a wide range of bonding needs and scenarios. Some of these include foam and fabric bonding, panel assembly, foam mattress manufacturing and many more. APAO hot melt adhesives are excellent in furniture manufacturing because they are low cost, are easy to dispense and allow for a wide range of open times to meet many application needs.

Why APAO Adhesives Excel in Furniture Assembly

- Low cost, high initial tack, excellent cohesion

- Flexible open time

- High productivity

- Easy to dispense

- Can be sprayed or dispensed as a bead

Popular APAO Hot Melts for Furniture Assembly

Mattress Assembly

- Infinity Bond IM-A6240: Formulated for bed in a box foam bonding

- Infinity Bond IM-A6280: Standard foam mattress assembly

Foam and Upholstery Bonding

- Infinity Bond IM-A6120: Medium open time, excellent heat resistance

- Infinity Bond IM-A6050: Very long open time, excellent heat resistance, sprayable

- Infinity Bond IM-A6240: Excellent foam bonding hot melt, bead or spray dispense

Panel Lamination

- Infinity Bond IM-A6290: Very long open time, high heat resistant sprayable APAO hot melt.

- Infinity Bond IM-A6020: Very long open time, sprayable APAO hot melt.

Edge Banding & Lamination

- Infinity Bond IM-A6290: Long open time, bead or spray dispense, high heat resistance

- Infinity Bond IM-A6020: Long open time, bead or spray dispense

Wire and Cable Assembly with APAO Hot Melts

The Wire and Cable industry uses a large number of adhesives for cable filling, fiber optic bonding, as flooding compounds and more. APAO is well suited to a large number of these applications because of excellent temperature resistance, ease-of-use, hardness/flexibility options and wide range of open times.

Why APAO Adhesives Excel in the Wire and Cable Industry

- Inherent moisture resistance prevents water penetration into the inner insulation

- Protects core of the cable

- Inhibits corrosion

- Can sustain a wide range of temperatures

- Acts as a cushion and a lubricant to protect cables from damage due to mechanical handling

- Prevents telescoping

- Provides cohesive bonding between external and metal jackets

Popular APAO Hot Melts for the Wire and Cable Industry

Filling, Flooding and Fiber Optic Bonding

- Infinity Bond IM-A6290: Very long open time, excellent heat resistance

- Infinity Bond IM-A6080: Medium open time, excellent cold resistance

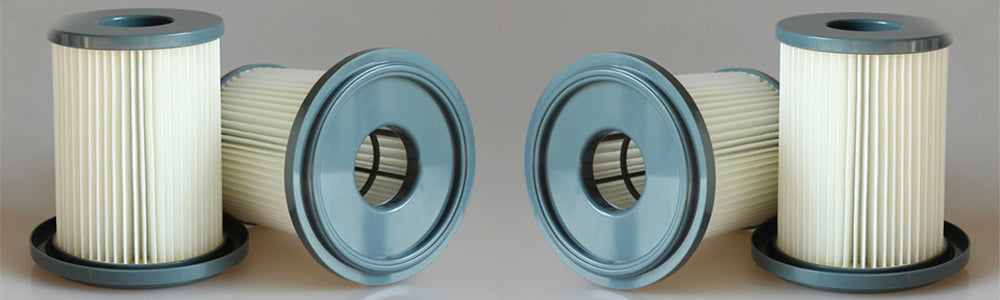

Filter Assembly Applications for APAO Hot Melts

Filters are a huge part of our world and can be found in homes, automobiles, pools and many other everyday products. APAO hot melts are an excellent way to assemble and manufacture a wide range of filters and are being used to replace much more expensive and difficult to dispense adhesives like polyamides. Some common filter applications include:

- Heating, AC and Ventilation (HVAC)

- Transportation Cabin Filter Assembly

- Water and Fluid Filter Assembly

Benefits of APAO Hot Melt for the Filter Industry

- Can often replace Polyamide hot melts significantly reducing costs and eliminating shelf-life issues

- Adhere to a variety of substrates

- Short, medium, long open time products to meet the application requirements

- Easy to apply – roll coat, spray, bead

- High heat resistance

- Excellent thermal stability

- Products can pass UL94V2

- Easy to process

- Low VOC

Popular APAO Hot Melts for the Filter Industry by Properties

- Infinity Bond IM-A6320: Low viscosity, short open time, high heat resistance

- Infinity Bond IM-A6080: Medium open time

- Infinity Bond IM-A6270: High viscosity, no stringing, short open time, high heat resistance, bonds difficult substrates

- Infinity Bond IM-A6120: Low viscosity, medium open time, high heat resistance, adheres to difficult substrates

- Infinity Bond IM-A6060: Low viscosity, medium open time, high heat resistance, adheres to difficult substrates

Low Pressure Molding APAO Hot Melts

Low Pressure Molding Systems

How to Dispense APAO Hot Melt

There's no magic to dispensing APAO hot melt adhesives. Depending on the application requirements, APAO hot melts can be dispensed from the same equipment as standard hot melt adhesives. The main consideration if moving to an APAO hot melt is making equipment adjustments to account for changes in potential softening points and viscosity.

Common APAO Hot Melt Dispensing Methods

- Bulk Hand Guns: electric and pneumatic versions available

- Bulk Dispensing Equipment

- Roll Coating Equipment

Questions on APAO Hot Melt Adhesives?

There's a lot to digest here on APAO hot melt adhesives and how they play into product assembly and manufacturing operations across the world. Hotmelt.com is the industry leader in APAO hot melt adhesives and we currently service customers using this chemistry in a wide range of industries across North America.

All of the pricing on Hotmelt.com APAO hot melt is for single case quantity. For a bulk quote or for help determining if APAO adhesives are right for you, contact one of our hot melt engineers for a free consultation.